Produces high-quality pellets with uniform color & properties

Versatile processing for multiple polymers and formulations

Reduces raw material cost with filler and additive integration

Enhances final product performance in extrusion, injection molding, and blow molding

Fully customizable line configuration (screw diameter, L/D ratio, pelletizer type, feeding systems)

High throughput & energy efficiency for large-scale production

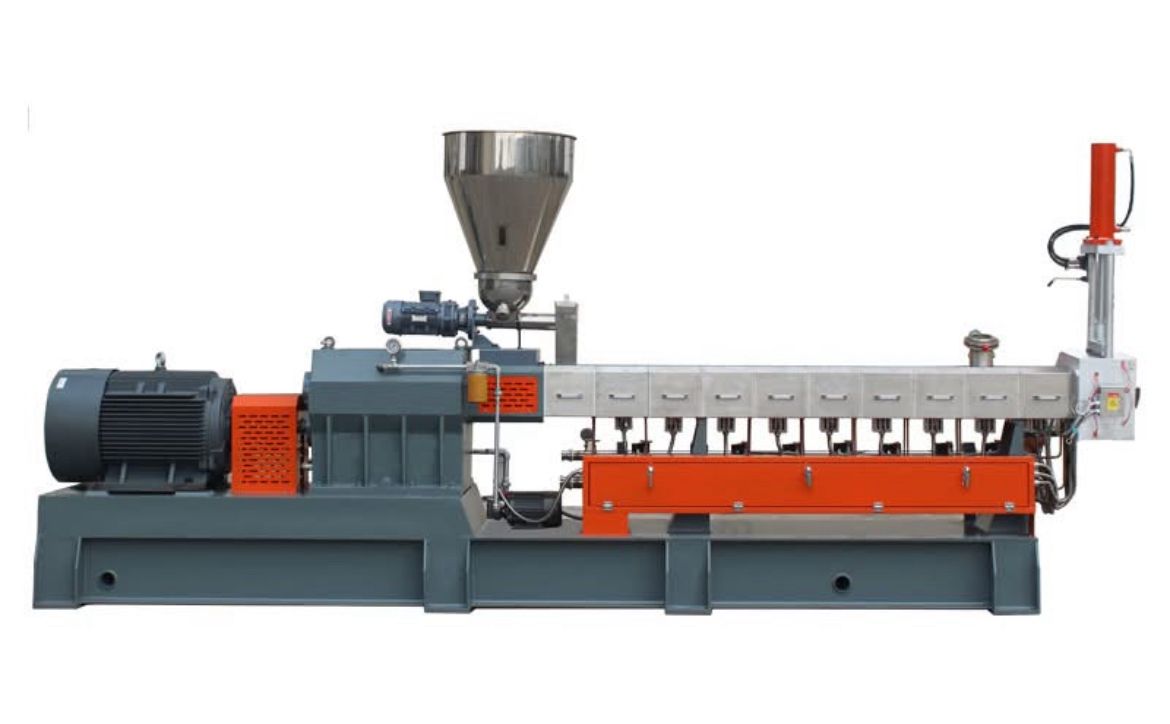

Twin-Screw Extruder Technology – Ensures superior mixing, dispersing, and compounding.

Flexible Formulation – Handles a wide range of polymers, pigments, fillers, and additives.

Accurate Dosing Systems – Gravimetric/volumetric feeders for precise ingredient feeding.

Efficient Pelletizing – Strand, water-ring, or underwater pelletizer options.

Advanced Control System – PLC/HMI automation with recipe storage for repeatable production.

Wear-Resistant Materials – Screws and barrels designed for high filler content and abrasive additives.

Energy Efficient Design – Optimized screw geometry reduces power consumption.

Color Masterbatch – For coloring thermoplastics with uniform pigment dispersion.

Additive Masterbatch – UV stabilizers, flame retardants, anti-static, slip agents, etc.

Filler Masterbatch – Talc, calcium carbonate, and other mineral-filled compounds.

Polymer Alloying & Blends – Custom formulations for enhanced properties.

Engineering Plastics Compounding – PP, PE, ABS, PC, Nylon, PET, etc.