Produces neat, uniform coils for easy storage & transportation

Automatic coil changeover ensures uninterrupted production

Saves time & labor in pipe handling

Suitable for high-speed extrusion lines

Available in cost-effective manual models for small-scale production

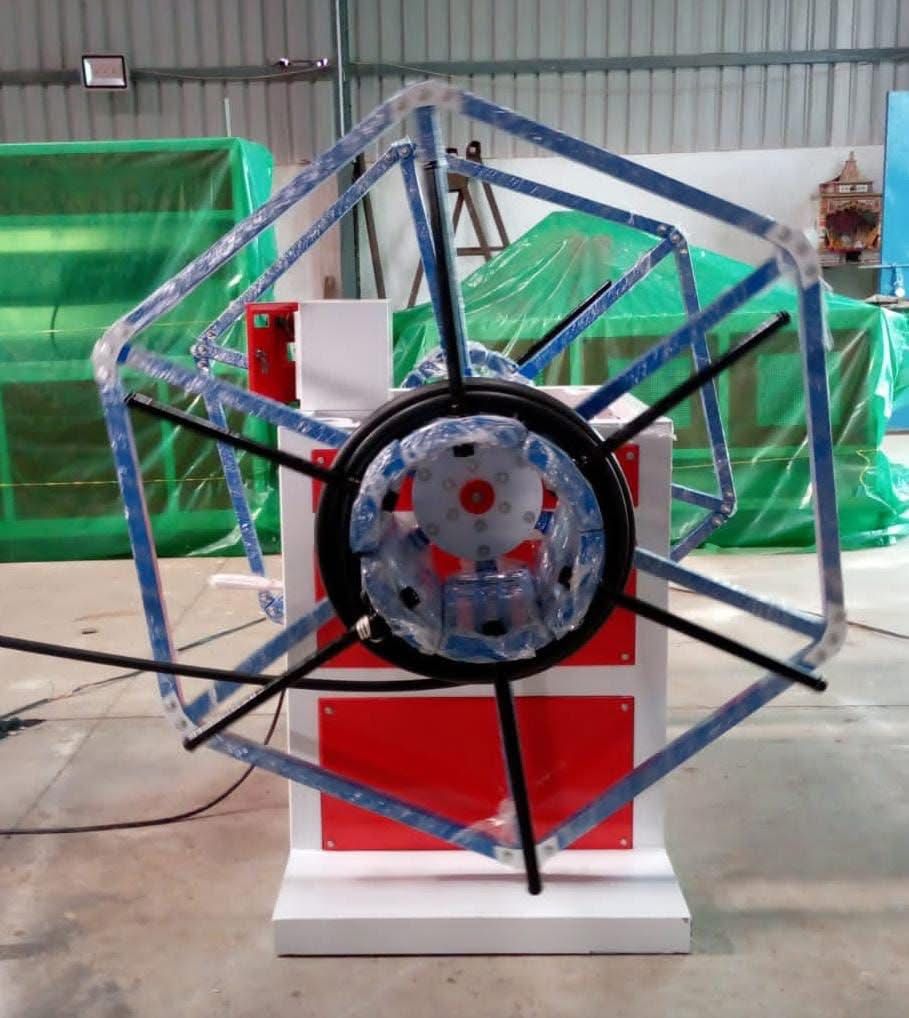

Automatic & Manual Options – Flexible choice depending on production requirements.

Synchronized Operation – Automatic coiler works in harmony with the extrusion line speed.

Dual Coiling Stations – Enables continuous operation without downtime.

Adjustable Tension Control – Ensures uniform coil winding without pipe deformation.

Safety Design – Equipped with protective covers and emergency stop system.

Heavy-Duty Structure – Built for long-term durability and low maintenance.

Easy Operation – PLC/HMI control for auto coilers; manual handle operation for basic models.

Winding of HDPE, LDPE, PPR, PVC and other small-diameter flexible pipes

Micro-irrigation pipes & drip tubes

Medical tubing

Electrical conduit pipes

Flexible hose manufacturing