Produces pipes with uniform diameter & smooth surface.

Enhances dimensional accuracy and stability.

Reduces pipe ovality & defects.

Improves production speed with efficient cooling.

Compatible with a wide range of pipe diameters & thicknesses.

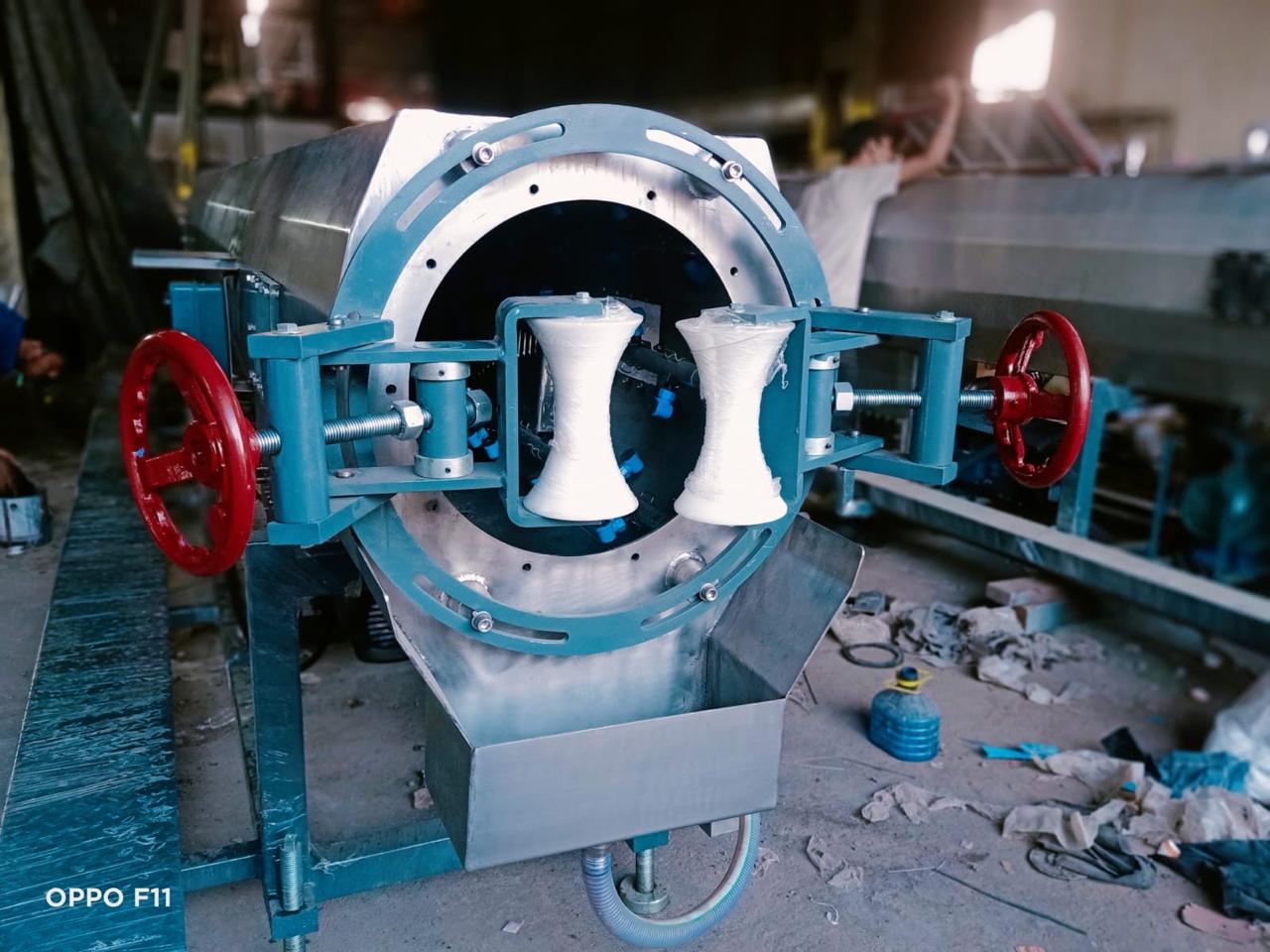

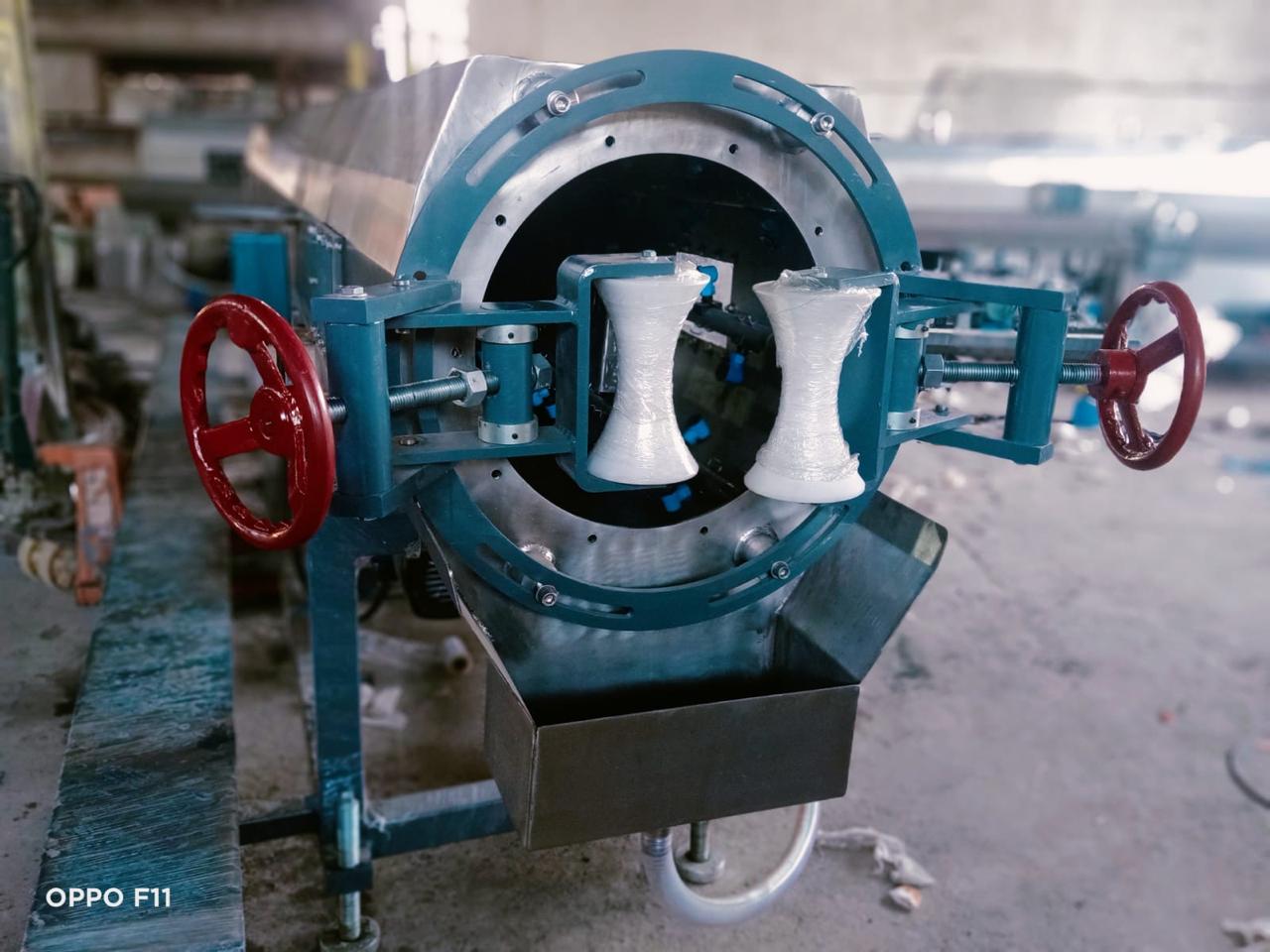

High-Precision Calibration – Ensures accurate pipe diameter and roundness.

Stainless Steel Construction – Corrosion-resistant and durable for long service life.

Multi-Chamber Design – Stable vacuum distribution for improved product quality.

Efficient Cooling System – High-capacity water spray and circulation for faster cooling.

Adjustable Pipe Supports – Smooth pipe guidance with quick adjustments for different sizes.

User-Friendly Control – Easy operation with PLC/Panel control system.

Sealed Design – Prevents water leakage and maintains stable vacuum conditions.

PVC Pipe Extrusion Lines

HDPE, PPR & Other Plastic Pipe Production

Conduit & Casing Pipes

Pressure & Non-Pressure Pipe Manufacturing